Sheet Meeting Services

(click on thumbnail to enlarge)

Sheet Meeting Services

(click on thumbnail to enlarge)

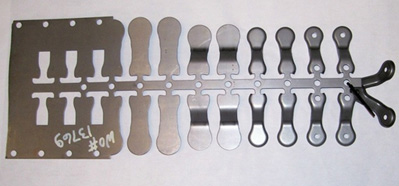

Committed to offering clients high-quality mechanical engineering services, Centaur provides precision sheet metal stamping services, as well as tool and die design and manufacturing capabilities. We build tooling for presses up to 600 tons in-house, and we can work with materials measuring up to eighty inches in width. Both our ISO compliant, sheet metal stamping services and tool and die manufacturing operations hold tolerances down to (+/-) .001 of an inch.

Our advanced software includes full FEA analytical proviron pills design and engineering for tooling that helps save our clients valuable time and money. Our FEA software analyzes design dies in a virtual platform, which lessens time spent on prototyping and experimentation. At Centaur Tool, we pride ourselves on the ability to manage all our clients’ manufacturing needs in a timely manner, from small to long runs and large scale production. Contact Centaur today to learn more about our precision sheet metal stamping capabilities or to inquire after our advanced tool and die design and manufacturing services.

Portfolios

Specifications

| General Capabilities | CAD Modeling (2-D, 3-D) Design Engineering Inspection Prototypes Testing Tool History Documentation Technical Support |

| Die Types | Stamping

Forming Dies Draw Dies Blanking Dies Secondary Dies Hand Transfer Dies Swaging Dies |

| Tooling | Checking Fixtures Welding Fixtures Inspection Gauges/Fixtures Assembly Fixtures Welding Fixtures Automation Equipment |

| Intended Application | Drawn Shells Pans Tubes Channels Perforated Shapes Embossing Engraving |

| Industry Standards | ISO - International Organization for Standardization |

| Material Applications | Aluminum Brass Copper CRS Kovar Spring Steel Stainless Steel |

| Production Volume | Specialty Production Shop Prototype Low Volume Small Run High Volume Large Run Long Run Large Scale Production Volume Run |

| File Formats | AutoCAD (DWG,DWZ) SolidWorks (SLDPRT,SLDDRW,SLDDRT) |

| Tonnage | Max 300 Ton In-house Try Out 600 Ton Max Tool |

| Length | Max 80 in |

| Max Part Weight | Max 20,000 lb |

| Tolerance (+/-) | 0.001 in |

back to top

Call:

Call: